- +971 4 837 83 81

- info@fandascientificme.com

OUR PRODUCTS

PSA300*

Static Image Analysis System Particle Size

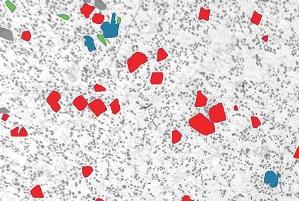

The HORIBA PSA300 is a state of the art turn-key image analysis solution. Seamless integration of Clemex’s powerful particle characterization software and an automated microscope with high-resolution camera creates an intuitive, easy-to-use imaging workstation. Addressing a need in the field of particle characterization, the PSA300 is a versatile particle size and particle shape analysis tool that can be used in a wide range of applications in the pharmaceutical industries and material science. It is a turn-key solution for labs that want to maintain an analytical microscopy environment with minimum intervention by the operator yet still yield maximum detail in the results.

*Available in the Americas. For additional information, please contact us.

- Particle shape information – Industry experts, especially pharmaceutical, are now looking to characterize particle shape in addition to particle size, to gain a better understanding of how shape can effect the various properties of a product. More are recognizing the significance of particle size and shape as well as their impact on the physical characteristics of many particulate materials. Process problems with drug substances can often be attributed to the particle size or shape of the active material.

- Sensitivity and accuracy – PSA300 features excellent resolution and detection of micronized particles as small as 0.5 microns. Our unique automated calibration routine assures complete validation of measurement accuracy in accordance with NIST standards. Particle volume determination is based on absolute 2D measurements and thus not limited to spheroids. Accurate volume measurements can be performed on elongated cylinders, acicular or irregular shaped objects.

- Repeatability – Microscope parameters and camera settings are saved as properties in the routine associated with each sample. In conjunction with an automated workstation, an image analysis routine can be executed multiple times with no deviation from the initial results. This guarantees reproducibility and traceability of analysis, ensuring accurate results and conforming to 21 CFR Part 11 requirements.

- High Throughput – Data collection is achieved through multiple field analysis using a Clemex 4-slide sample holder and motorized stage. Our robotic image analysis system will allow the user to measure large number of slides simultaneously without any operator intervention.

- Results Management – PSA300 automatically calculates various measurements simultaneously on thousands of individual particles. It is capable of generating statistically significant results in an amazingly short time. The powerful report generator allows speedy data processing and flexible reporting capabilities.

- Security and Compliance – PSA300 allows the management of user rights, audit trail of critical interventions, electronic signatures as well as overwrite protection of all electronic documents produced by PSA300 imaging workstation (images, stage patterns, image analysis routines, raw binary data, image analysis report in PDF). Traceability is assured by saving all analysis settings, data, results, and images (if required) in the same protected file. All of these security features are designed to conform to regulatory requirements such as FDA 21 CFR part 11 ensuring data integrity.

| Size Range | 0.5-1000 µm |

| Objectives | 2.5X, 5X, 10X, 20X and 50X. |

| Automation | Computer controlled Motorized nosepiece, Computer controlled Motorized condenser, Computer controlled Motorized focus, 0.05mic/step, Motorized stage 215 x 75 mm travel, 0.5 mic/step, CLEMEX Motorized stage controller assembly. |

| Measurement Time | Between 2 and 30 minutes depending on particle size and number of particles analyzed. |

Principle of Operation

The use of automated image analysis is increasingly being recognized as an attractive technique to characterize particle shape and size distribution. Traditional methods, such as laser diffraction, although highly efficient, give limited information on particle shape proving image analysis as the best tool for performing particle analysis.

Accessories

Disperser Unit – An automated sample disperser subjects powder samples to a controlled quantity of force by subjecting the sample to a burst of air as a vacuum is released. The sample disperser breaks agglomerates and assures an even spread of sample across the slide. Unit includes disperser column, two slides base, high vacuum dry pump assembly, and USB computer control unit and software.

Similar Products

Related products

-

Fluorolog-QM

Learn moreModular Research Fluorometer for Lifetime and Steady State Measurements

-

Aqualog – A-TEEM Industrial QC/QA Analyzer

Learn moreA Simple, Fast, “Column Free” Molecular Fingerprinting Technology

-

Aqualog – Water Treatment Plant Analyzer

Learn moreAutomated Organic Analysis & Early Warning Sentinel